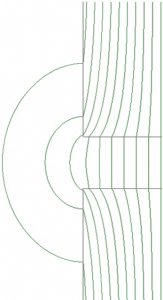

At the WoW conference during the Wireless Power Week, we presented two papers on the power handling capability and feasibility space of multilayer self-resonant structures (MSRS) for practical wireless power transfer (WPT) applications. A MSRS comprises many thin foil conductors with capacitive ballasting and equal current sharing among the layers and has demonstrated quality factor multiple times higher than similar size conventional WPT coils found in the literature.

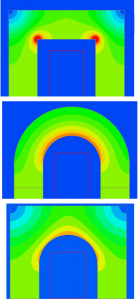

First, we explore the power handling capability of the structure considering various large signal effects. These effects include nonlinear magnetic core loss, temperature rise and temperature dependence of losses. The analysis shows that the MSRS has a power capability at least 3 times higher than conventional WPT coils of similar size and thermal performance. A WPT system comprising two MSRS with 6.6 cm diameter and 3.5 mm thickness was able to transfer as much as 172 W over a distance of 3.3 cm (range/diameter = 0.5) when the measured surface temperature was 68 °C. The power capability is higher for shorter power transfer distance; the analysis shows that as high as 10 kW can be transferred over a 5 mm distance. Link to full paper

Second, we explore the minimum feasible resonant frequency and the maximum power level without dielectric breakdown that can be achieved using the MSRS given a size constraint. This analysis is applied to two case studies; one for consumer electronics and one for electric vehicles. The example MSRS for electric vehicles has a diameter of 20 cm and height of 5 cm. If a 100 kHz resonant frequency is selected, the MSRS can achieve an output power of 10 kW at a range of 20 cm with an input voltage of 500 V. Link to full paper