We’ve published a lot of papers on litz wire. Their emphasis has been academic, reporting new optimization results and calculation techniques. But they are are often too complex for design work, for an engineer who has many different issues to deal with. With that in mind, we took a different approach in a paper presented at APEC 2014, focusing on making the simplest possible design method that would still provide good practical guidance of litz wire design. We found a way to incorporate the results of some of our more sophisticated analysis into simple formulas that can be quickly and easily calculated in a spreadsheet or the like, so that you can get good recommendation for litz designs very easily.

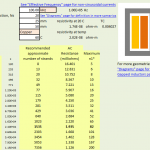

The full paper is available on our web site. The first two pages are all you need to read to get complete instructions on the method. To demonstrate how easy it is to use in a spreadsheet, here is the method implemented in a spreadsheet. You only need to put in four numbers–frequency, number of turns, core window breadth and turn length–and you get a range of options with the performance of each listed.

The simplest calculation is for a transformer winding, but the paper and the spreadsheet also include calculations for gapped inductors, accounting for the field in the region of the gap. Similarly the base method is for sinusoidal currents, but both include an easy adjustment to deal with nonsinusoidal waveforms.

There are some situations that this method can’t deal with–for example, if you have an unusual geometry, or multiple windings with different current waveforms in each winding. In those cases, our online LitzOpt calculator (which has recently been updated to be a little more robust and user friendly) can address most situations directly, or pretty much any situation in combination with an external field simulation.

In addition to being easier to use, the new method also features a calculation that helps you choose some of the details of the wire construction–how many strands are twisted together in each step. Typically one might combine somewhere between 7 and 50 strands in the first step, and then twist several of those bunches together in the second step, etc. The details of this sequence affect how well the wire eliminates skin effect. The later twisting steps should never combine more than 5 bundles together, but it’s often OK combine many 10s of strands in the first step. The new calculations tell you how many it’s OK to combine in that first step.

Another choice in the construction is the pitch of twisting at each step. This paper and spreadsheet don’t provide any guidance on that, but we are publishing a new paper on that topic at COMPEL 2014. That paper will appear here soon after the conference.

T