Of the three main component types needed in power converters—switches, capacitors and inductors—the most difficult to integrate on a semiconductor chip or in a planar package is the inductors. This difficulty arises partly from process compatibility challenges with magnetic materials, and is exacerbated by the fact that, because most types of electronics don’t need inductors, there has been relatively little development effort. But a more fundamental challenge is the way magnetics performance scales with size.

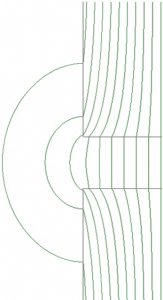

Capacitors and semiconductor devices can be made from thousands of small cells connected in parallel, but that approach would severely undercut the performance of magnetic components.

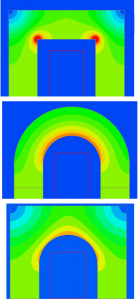

In this work, we examine the scaling relationships for magnetics to demonstrate the inherent difficulty of small size and low profile magnetics. Cases considered include those with winding designs limited by skin and proximity effect and those constrained by efficiency and thermal dissipation. Small-scale magnetic components are typically limited by efficiency rather than heat dissipation. With efficiency constrained, and considering high frequency winding loss effects, it is shown that power density typically scales as the linear dimension scaling factor to the fifth power.

For the full analysis, see the attached paper, Sullivan, C.R., Reese, B.A., Stein, A.L. and Kyaw, P.A.,. “On size and magnetics: Why small efficient power inductors are rare.” IEEE International Symposium on 3D Power Electronics Integration and Manufacturing (3D-PEIM), 2016.